OceanX@Fruit Logistica 2020 – Event Report

OceanX was proud to be part of the Logistics Hub at Fruit Logistica in Berlin last week, presenting OceanX and participating in the panel discussion on industry digitalisation and the advance of digital forwarding.

With more than 72,000 visitors and over 3,300 exhibitors the leading event in the perishable supply chain, bringing together growers, traders, suppliers and logistics service providers, Fruit Logistica 2020 was an exciting experience. Whilst also impacted by the Corona Virus to the degree of mandatory health declarations and the last minute absence of much of the Chinese delegations, it remained a very busy week, drawing a huge audience, despite a notable shortfall of Asian visitors.

OceanX was part of the Logistics HUB, where over 3 days, 10 current issues of the perishable supply chain were elaborated by 20 presenters and debated in two panel discussions, moderated by Alexander von Stempel.

Ruben Huber presented the OceanX network and it’s aspiration to move beyond bilateral facilitation being a think tank for members, sharing best practices and supporting in digitalisation and internationalisation. Illustrating some of the members and their cool chain logistics activities, he outlined 8 case studies from members in different parts of the world, providing services at the export or import side of the perishable and fruit supply chain:

Dynamic Group and their export services for Chaunsa mangoes and oranges from Pakistan, FM Global Logistics in Malaysia and their activities in tropical fruit exports, JackyLine in Israel and their controlled atmosphere solutions for Citrus, Avocados, Magoes, Dates, Pomegranates, Potatoes, Carrots and Peppers, Logfret in Poland and their export services for Apples, Pears and Blueberries, Navia in Australia and their foodstuffs distribution services and visibility solutions for customers, Mercator in Argentina and their outbound services for fresh Tucuman Lemons, Van der Helm’s division TrofiPack and their packaging, ripening, storage and distribution services for Avocados and Mangoes at their new cool storage facility in Den Hoorn, Netherlands, as well as World Jaguar and their import, storage and distribution services to the largest consumer market on the planet, China.

Ruben afterwards joined a panel discussion with Anne-Sophie Zerlag-Karlsen from Maersk’s digital freight forwarder TWILL, Mike Dempsey from IoT leader Orbcomm and Jack Fleming from digital cold chain solutions startup Chill-Chain, on industry digitalisation.

Whilst Anne-Sophie somehow did not get an opportunity to show what she is up for with TWILL, but the transition from liner heels (she used to head the reefer division at Maersk Line previously) to startup sneakers seems having been well accomplished already. Further she made two significant and inspiring points during the discussion: First on the need to create demand, by providing solutions that customers need but did not know are possible. Thus a clear focus on innovation and shift from the cost focus that the liner industry had for too long, to a value adding discussion. Second, on speed, which is essential and which is driven by this demand.

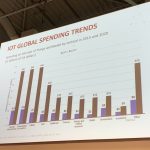

Mike Dempsey from Orbcomm, provided an exciting overview on reefer and sensor technology. He illustrated how the advance of controlled atmosphere boxes has changed the cargo that is being carried, constantly containerising new commodities that used to be flown or had a limited market for distribution previously. He also outlined how IoT has become mainstream, as RFID is turning 20 years old, most reefer trucks have technology in the third generation now and by end of the year 40% of the global reefer fleet will have some kind of IoT device, while almost all ships are connected now. In 2020, IoT in transportation and logistics will become a 40 billion USD market.

Jack Fleming nicely arguments the importance of the business model over the technology, why is something done and for what purpose, to solve what problem. Chill-Chain thereby is taking a very customer focused approach in what they are doing, cold chain asset utilisation optimisation, in the last mile. In fact they act as a broker, marketplace, service provider or consultant, adapting to a need, rather than selling a product.

An open question on „waste“, allowed for a bit of a segmentation by the panelists:

food waste = More related to consumption habits, last mile, shop to fork, anytime availability convenience and oversupply.

food loss = Happening during the process of transit from farm to shop, where temperature, controlled atmospheres, packaging etc can help to minimise.

packaging waste = To preserve food and/or to meet convenience requirements of consumers, the perishable supply chain does create a lot of waste.

opportunity or efficiency waste = For example empty truck legs, low turnaround of reefer equipment, etc.

And fighting waste in these different forms, is lastly what makes the perishable supply chain so exciting for innovation, as any waste reduction allows everyone to win.

The event was also opportunity to catch up with several shipping lines, reefer suppliers and technology companies, thus some further exciting insights below:

- The fact that one third of our food does go to waste remains a shocking reality and knowing this, should make us smarter consumers.

- One of the best presentations at the Logistics Hub was definitely that by ONE container line, providing a comprehensive overview of the reefer market.

- Cool chain expert and OceanX ambassador Alfred Cheung provided an exciting update on refrigeration technology based on the example of rail transportation in Japan. He introduced the audience to two key technologies for the future, outside of controlled temperature and controlled atmosphere: Proton Alignment and Electric Field Technology. Further he provided some insights on the use of Sea Snow, where frozen seawater and different temperature settings can improve fish and seafood quality preservation significantly.

- Sustainability becomes a key focus and more than lip service. Bruce Marshall of Maersk Line, outlined impressively how it will be a key pillar of their strategy forward. Presenting Maersk ECO Delivery, he showcased a real product of carbon neutral transport using Biofuels, where they have completed successful trials with several customers (e.g. H&M, DSM, Philips, Unilever) recently and see a serious amount of interest within their top 150 clients. He compared to process illustratively to the buying on green energy, where the power mix is based on what customers require and pay for. Partnerships are essential for the product, as even Maersk does not control the entire supply chain and independent certification is an asset.

- Stavros Evangelakakis of Cargolux and Chairman of the Cool Chain Association, gave an interesting overview of the perishable market for airfreight, which has reached 6.8 million kgs worldwide in 2018/2019, comparing with pharma products of 1.3 million kgs. In his further comparison between the two sectors, he managed to illustrate the key difference in the two segments: Whereas for pharmaceuticals the original shipper’s name is on the product from production to market, clearly aligning responsibility of the end to end cool chain to ultimately one party, for the perishable supply chain, this is not the case. It stretches over several parties, that need to harmonise and whose interests must be aligned. Shippers in the pharma supply chain, do follow the chain and visit each step to ensure end to end quality, which in perishables remains the exception. Thus even if an airline does a great job, certain steps outside their control, e.g. the average 108 m transit between airplane and cold storage or the temperature that the cargo is delivered with.

- Hapag Lloyd „LIVE“ was presented, which is based on Globetracker technology and illustrates how these guys are on a run currently. Had the opportunity to have a peak at what is up next, where the container sensor will become the gateway for loggers that are inside different packages of the cargo and thus enable much better data on the cargo live streamed via the container and vessel, from inside the unit.

- Loginno seems to progress nicely with their digitalisation of Log-In’s container fleet, also further developing side services like VGM container weight calculation based on sensor data and cyber seal.

- Meetings with two interesting tracker and datalogger companies, that both have exciting devices, mainly aiming for shippers: TIVE.co and Friggatech.com

- A lot of focus in terms of tech, remains on visibility. However visibility itself adds little value, however sexy a map with all your running shipments might appear. If visibility enables faster reaction, e.g. allowing replacement shipment by ocean instead of air, it starts generating value. And any solution must create sufficient value of this kind, to justify investments in visibility and monitoring solutions.

- The innovation price went to Syngenta’s Yoom Tomato, followed by Silbo, a polish packaging innovation that enables fully compostable packaging solution. Third place went to SoFroMinipak, also for an environmentally friendly packaging, indicating how much innovation goes into waste reduction currently.

About OceanX

OceanX is a non – exclusive global network of leading ocean freight providers and NVOCCs dedicated to delivering bespoke innovative solutions, in particular on FCL services, LCL consolidation, dangerous goods and chemical logistics, temperature control, as well as project cargo handling.

OceanX Presentation File / Fruit Logistica 2020